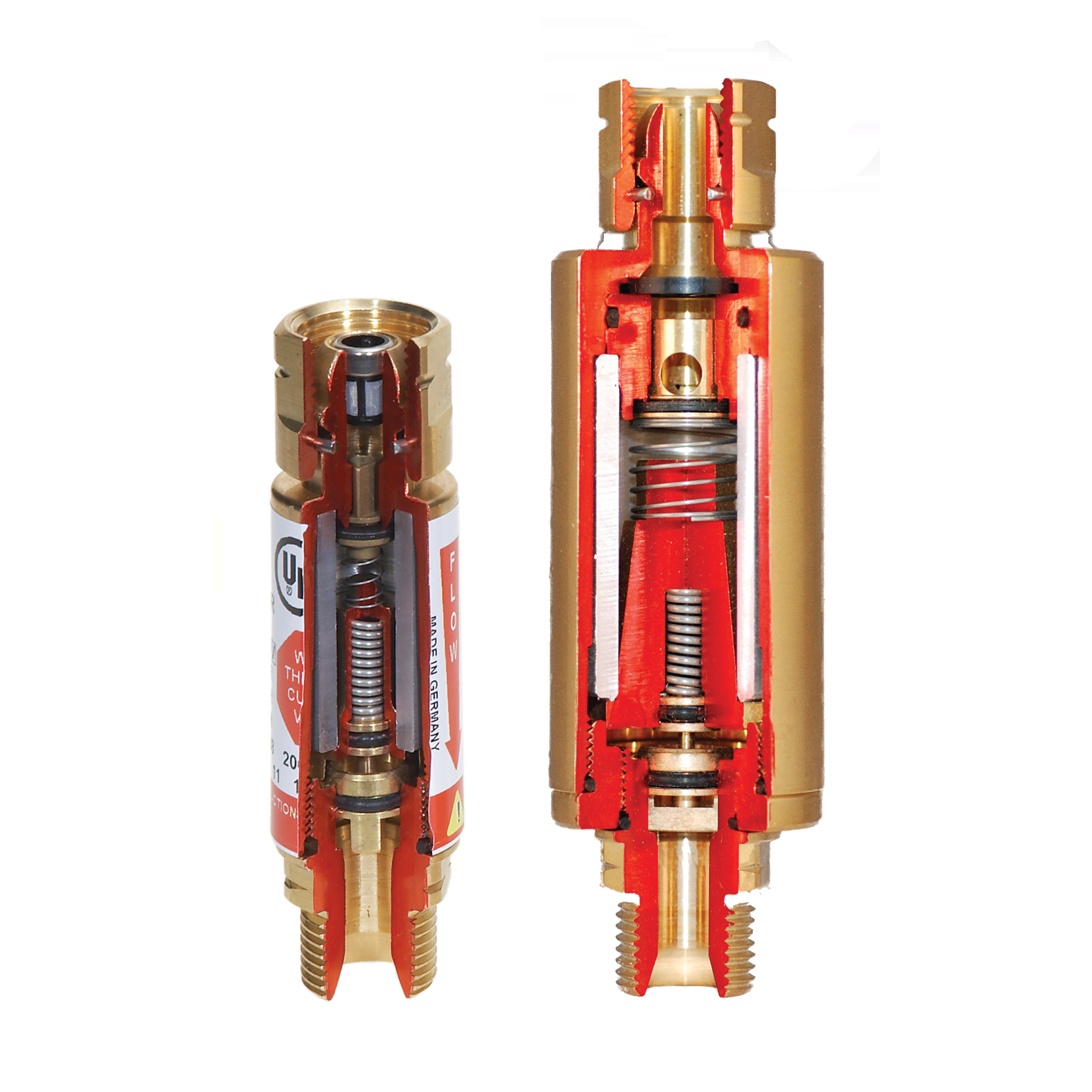

Category: High Flow Flashback Arrestors

The Importance of High Flow Flashback Arrestors

Ensure safe operation with high flow flashback arrestors, providing proper gas flow for larger tips and longer service life for heating and

Loading...

Be the first to know about new products and industry news