Category: Welding

What size flashback arrestor do I need?

SuperFlash Compressed Gas Equipment offers High Flow Flashback Arrestors for use on both the torch side and

Plasma Cutting vs. Laser Cutting

Plasma and Laser - both choices offer great solutions for cutting different metals but which one is right for

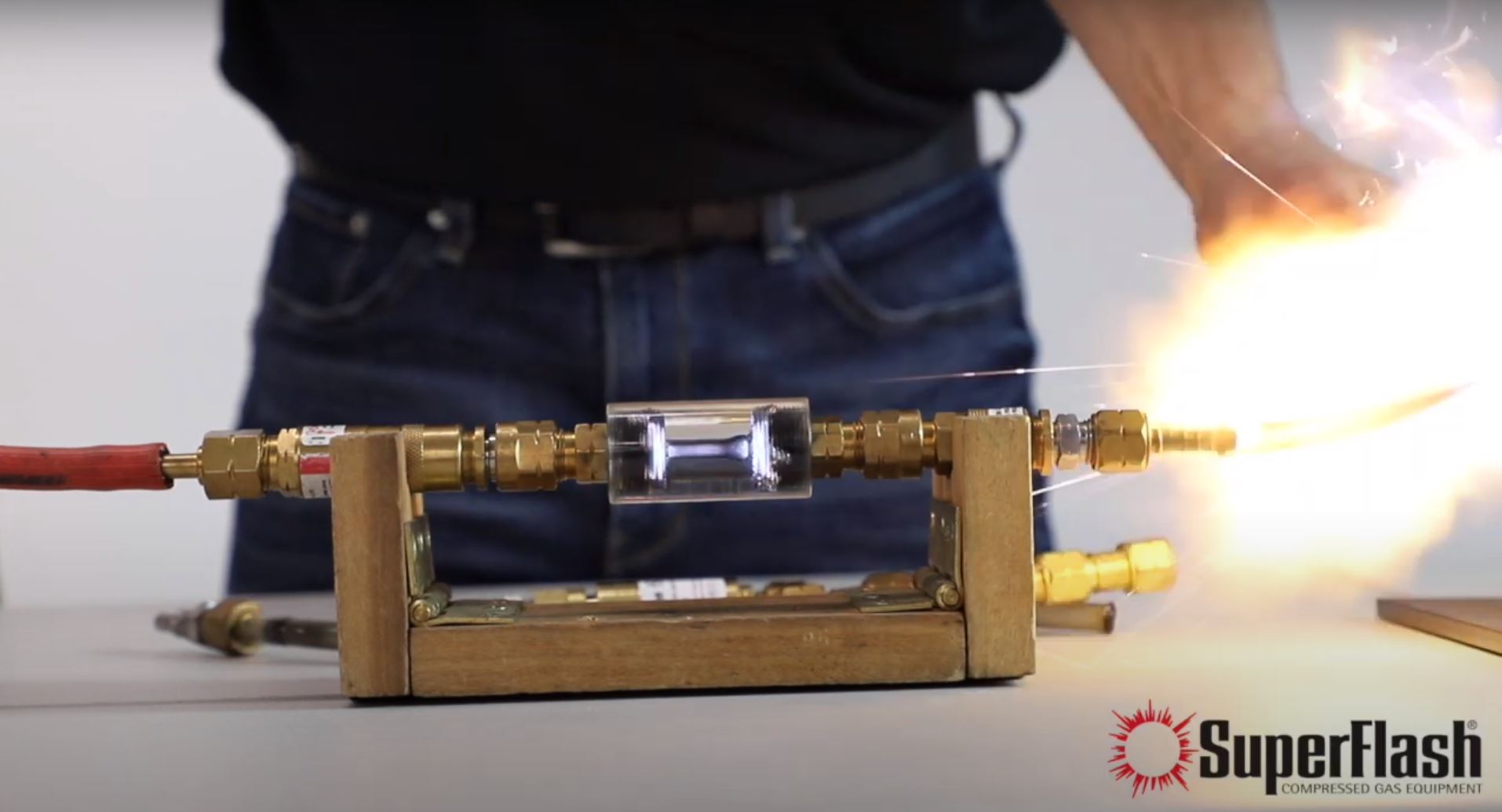

New! Oxy-Fuel Gas Safety Demos

SuperFlash flashback arrestors provide top safety with 3-5 micron flame barriers, reverse flow check valves, and 100% real-world flashback

Join Us at FabTech

Join SuperFlash at FABTECH 2019 in Chicago! Visit Booth #B33077 to see our Super Shield Gas Mixer and explore the future of metal

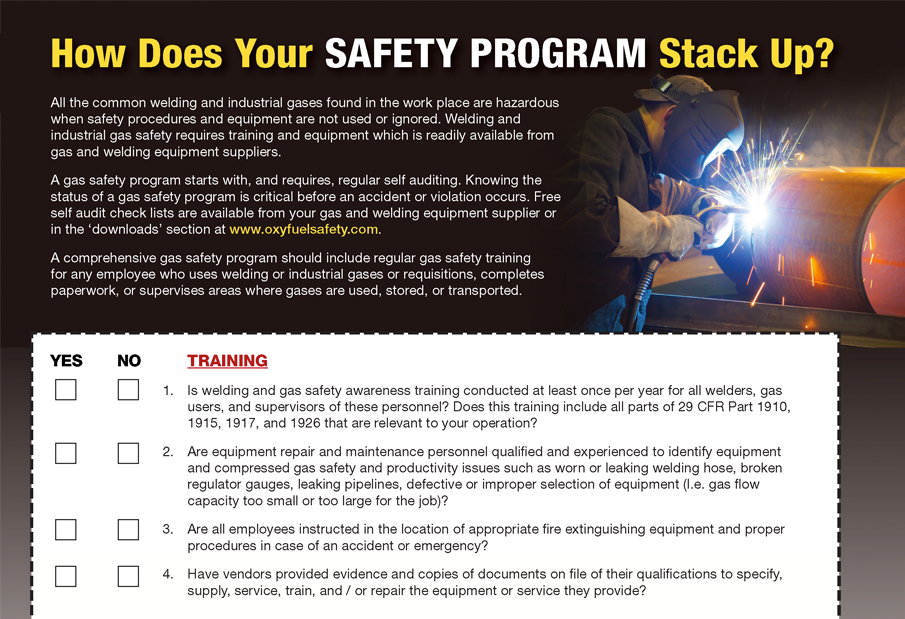

How Does Your Safety Program Stack Up?

Download this comprehensive Safety Program comparison to see if its time for you to switch over to SuperFlash

Introducing the iMixone Gas Mixer!

iMixone with integrated high-pressure regulators and flow control Gas mixer with diffusion-mixing system for two gases with up to three pre-set mixing ratios, especially for welding processes. The SuperFlash iMixone is used, for example, in the production of mixed gases for protective gas welding and covers the most frequently used gas mixtures for the MIG, MAG, TIG welding. Due to the mixing principle, this mixer also ensures a constant gas mixture even if the volume of gas withdrawal changes. Avoid additional energy costs with the iMixone! ADVANTAGES High mixing precision even if the volume of gas withdrawal changes Up to 3 mixing ratios can be pre-set according to customer‘s requirement Cost savings due to the avoidance of storage of different premixes Gas inlet filters protect the device against contamination Diffusion-mixing principle, no power supply required Withdrawal of mixed gas from 5 l/min up to maximum capacity Sturdy, compact design Low maintenance EASY HANDLING Direct connection to gas cylinders Straightforward use due to two integrated high-pressure regulators and high-pressure hose Selector switch for selecting the pre-set mixture HIGH PROCESS RELIABILITY Does not depend on the input pressure difference due to integrated constant pressure regulation Does not depend on gas withdrawal variations Mixture production stops automatically when gas supply is interrupted For more information, please email