Month: August 2014

New Spark Speaks Online Classes

SuperFlash adds 3 new FREE gas safety courses to its 'Spark Speaks' series, covering compressed gas safety, flashback arrestors, and accident

Introducing Free Online Welding and Gas Safety Classes From SuperFlash

Join SuperFlash's NEW "Spark Speaks" free online courses on welding and gas safety! Perfect for welders and supervisors. Call

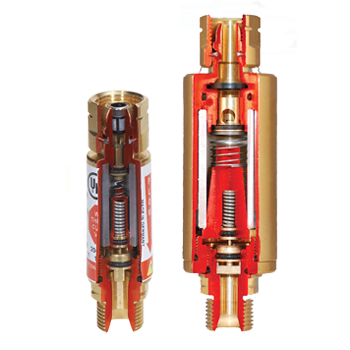

Why Are High Flow Flashback Arrestors Important?

Ensure safe operation with high flow flashback arrestors, designed for larger tips and increased gas flow, reducing backfires and equipment

Loading...

Be the first to know about new products and industry news