DGN Flashback Arrestors FAQs

Frequently Asked Questions:

1. Why do I need flashback arrestors?

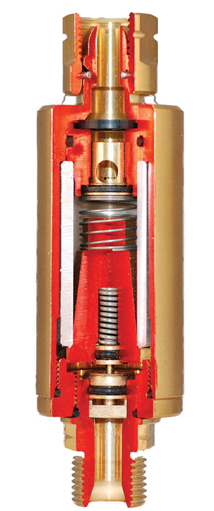

Answer: If the torch and/or regulator are misused, an accident called a flashback could occur. A flashback is an ignition of mixed gases which flows back to the source of the gases such as the hose, regulator, and cylinder at a speed which is greater than five times the speed of sound, creating the risk of injury or equipment damage.

2. Why aren’t flashback arrestors built in the torch or regulator?

Answer: Flashback arrestors should be checked on a routine basis to ensure they continue to offer maximum protection. If arrestors were an integral part of the torch, it would require the torch to be taken out of service for routine inspection. External flashback arrestors are much easier to replace even in the field and because they are external to the torch, can have larger component parts for higher flow, and longer service life.

3. Why is high gas flow capacity important when choosing a flashback arrestor?

Answer: High flow capacity flashback arrestors allow sufficient gas flow for larger heating and cutting tips. Additionally they have significantly longer service life because of their high flow capacity. A flashback arrestor can restrict gas flow if it is too small for the application, causing backfires, short tip life, poor quality work, and even equipment damage.

4. Why aren’t flashback arrestors required by law or in the U. S., OSHA safety regulation?

Answer: OSHA has cited employers for failure to use flashback arrestors under the broad federal regulation 29 CFR 1910.252, failure to recognize the responsibility to provide for the safe use of gas cutting and welding equipment. (Click here for more information on federal regulation 29 CFR 1910.252.)

5. Are flashback arrestors expensive?

Answer: A set of flashback arrestors for a torch or regulator usually costs less than a new regulator. However, they provide years of automatic protection against many types of accidents including flashbacks, reverse flow of hazardous gases, hose fires (when equipped with a thermal shut off) which could lead to lost time accidents, and equipment damage far exceeding their cost. By any measure, they are a good investment, which will pay off for many years with routine maintenance.