New Leak Testing Equipment Increases Production In Germany

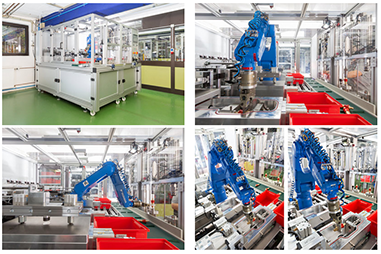

IBEDA Germany has New Helium-Vacuum Leak Testing Equipment that has increased production capacity by 50%, thus allowing for further investment in automated manufacturing of gas non-return valves (check valves), gas safety devices and quick action couplings.

With the new Helium-Vacuum leak testing equipment, production of IBEDA finished product has increased by 50%. This will enable increased fulfillment for the rising demands of high quality safety devices and quick couplers, while keeping reliable delivery and ensuring availability of 100% tested high quality products.

Every IBEDA arrestor is submitted

to a flashback test. With the new test equipment, each unit is additionally tested for slow reverse flow of gas

(≤ 50cm³/h), for external gas tightness

(≤ 8cm³/h), for a proper reset function (for products with pressure sensitive cut-off valve) and for leaks once this valve is released (≤ 50cm³/h). Hose couplings with shut-off valves are tested for leaks (≤ 10cm³/h) in both the coupled and uncoupled state. The leak test procedure is carried out at the maximum allowable operational pressure.

During the test procedure with Helium in a vacuum chamber, leaks can be detected far below the required values of 8 cm³/h for the external gas tightness, or 10 cm³/h for the shut-off valves of hose couplings according to EN561, or 50 cm³/h for the gas non-return valves of flashback arrestors according to EN730. These test procedures ensure that all IBEDA gas safety devices which are BAM and UL certified meet the high quality demands our customers have relied on for decades.